The Planet Indigo Sphere

- Ani Wells

- Jul 26, 2021

- 4 min read

Updated: Jan 11, 2022

"Closing the loop" is a wildly exciting concept for anyone looking to curb fashion's gigantic waste problem. The pie-in-the-sky idea of circularity gives us the hope that we can produce as much as we want, as long as it gets cycled back into the system somehow. But, this isn't the case, and we can't have true circularity until all stakeholders understand what circularity is. Part of the equation involves taking the consumer through the entire journey of a jean to show them their role in creating circular denim. Because they are a crucial piece in this puzzle. Is something circular if its journey ends with you? But most importantly, we all have to be vulnerable.

What do I mean by being vulnerable? It means getting outside of our comfort zones and unlearning what we have been taught our whole lives to make room for change. We must also be open to admitting where we need help and break down our egos to make room for strategic partnerships that take innovation to the next level.

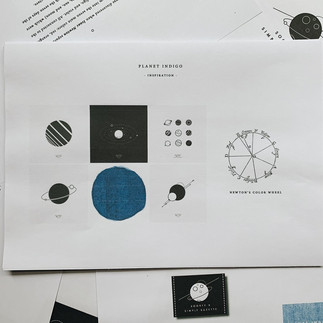

To put these concepts to the test, Soorty and I have developed Planet Indigo. A ten-piece collection that shows you how a completely transparent collection is made in detail, including all the people involved along the way, all of the inputs and outputs, while being able to trace everything back to its source.

We started by choosing only plant-based fibres with a focus on organic, BCI and recycled cotton, as well as Tencel, Linen and Hemp. It was a dream to use organic cotton knowing about the work being done behind Soorty's new initiative SOCI (Soorty's Organic Cotton Initiative) with the first harvest coming up next October. SOCI is all about uplifting farming families with a higher income, better schooling and access to professional health services, in conjunction with transforming the way cotton buying is conducted through blockchain-based traceability and digital marketplace. Its organic initiative is currently in the period of “transition cotton” as the experts call it, but will bring approximately 7,000 acres under organic cultivation producing over 17,000 metric tons of seed cotton and 6,000 metric tons of cotton lint over the next four years.

During Kingpins24, we were able to show you how Hemp and Tencel are spun together, but an important note here is that a lot of fibre gets lost during this step! Having a collection system to reuse lost fibre (aka pre-consumer waste) is very important and has allowed Soorty to eliminate a great deal of virgin fibre for their fabrics.

Moving on, we used Smart Indigo, which uses an electrochemical process to reduce the indigo pigment without the need for chemicals like sodium hydrosulphite. All that is needed is indigo pigment, caustic soda, water and electricity to create the dyestuff in a fully automated process! This means that the wastewater discharged does not contain the alarming chemicals that usually come with it, allowing for the reuse and recycling of the water used during the process. Think cleaner water channels, cleaner air, better soil health, better food and products for us all.

After carefully considering all of the materials, we went into production at the infamous Denim Kind facility. This LEED Platinum-certified production facility is highly powered by solar energy (950KW), repurposes 90% of the waste it produces, and recycles 85% of its water input in addition to collecting rainwater ☔ The recycled water isn't only good for denim production, but it is so clean the water has been classified as drinkable!

Denim Kind has invested $120 million in sustainable innovations and through this has installed state-of-the-art washing machines that work on less energy and reduced water usage through tech like lasers and ozone finishing while thoroughly screening chemicals from ZDHC compliant suppliers. No PP spray here!

In the Planet Indigo collection, we used SMART BLUE technology that carries chemicals onto the garment via foam versus water. This saved an average of 80% of water per laundry. All the processes are also conducted at room temperature with minimal steps to keep the energy needs extremely low and increase efficiency. 3x to be exact 🤓 On the finished garment, you can see the impact of each wash by scanning the QR codes.

With all of the effort that went into making this collection possible, it was essential to me to show the humans involved in every step and a bill of materials showcasing all the inputs including where they came from. That's why we decided to make a diary for each garment that displays all the people involved from concept ideation to scraping the final distressed details, and all of the materials plus their sources. We also created individual care tags for each piece to show users how they can extend that pieces' use phase and life expectancy.

Creating reverse logistics is an area we have been very vulnerable in. Still, we are developing the right partnerships for repair and refurbishment services, upcycling services once they can no longer be repaired, and assessing the impact of sending garments back to Soorty for end-of-life recycling to bring the materials back into the supply chain system for use.

FOR AN OVERVIEW OF PLANET INDIGO, SCAN THE QR CODE OR CLICK THIS LINK. HERE YOU WILL FIND THE STORY BEHIND EACH PIECE AND ITS ATTRIBUTES 🪐

This is just a glimpse into all the steps needed to create a truly circular collection, but it highlights how many people and processes are needed to succeed. We have plans to evolve Planet Indigo into a learning platform where we can freely exchange ideas and help each other solve the roadblocks to creating the best jeans on earth! So, keep your eyes out and please do share your comments on how you would improve this collection. It’s about being vulnerable, right!?

Until next time friends, always be curious and STAY DILIGENT!

Psssst: sharing the photoshoot of the actual pieces 👖😋

コメント